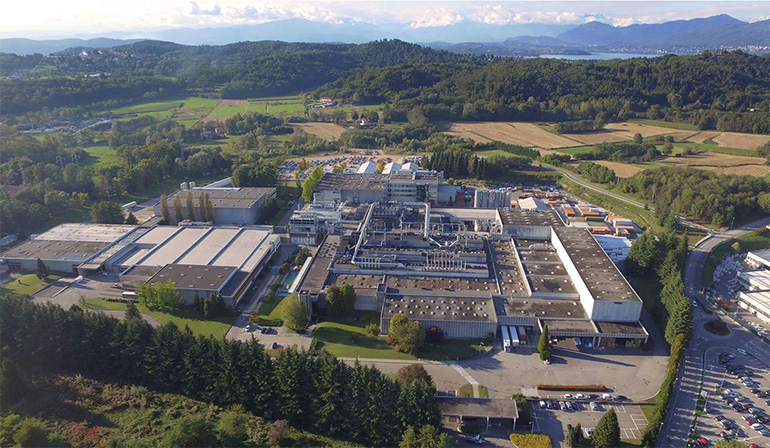

Goglio S.p.A. is a world leader in flexible packaging.

Founded in 1850, the Group designs, develops and manufactures complete packaging systems, supplying flexible laminates, plastic accessories, advanced lines and services for a wide variety of packaging needs, suitable for numerous industrial sectors: coffee, food, aseptic, chemicals, cosmetics, detergents, beverages and pet food. Goglio, which in 2023 recorded a production value of around 486 million euros, has over 2000 employees worldwide with production sites in Italy, Holland, United States, Brazil and China, and sales offices located in various European countries, in South America and in Asia.

The core of Goglio’s offer is the integrated packaging system designed by the company to offer customers complete solutions, implemented thanks to recent significant updates of the MIND Industrial Internet of Things platform: not only packaging laminates and lines, but also advanced services and technical assistance in every stage of the product’s life, offering a guarantee of efficiency thanks to Industry 4.0 solutions.

Goglio’s flexible packaging solutions are characterised by clear advantages in terms of sustainability and practicality - thanks to the constant work of the Research and Development team in designing and developing innovative solutions, such as the “recycle ready” packs in polyolefin or single-material (polyethylene or polypropylene) multilayer laminates - and allow for the transport of a greater quantity of product with less space and weight compared to traditional packaging forms.

Settori di destinazione

Merceologia

- 1.A. MATERIALS AND AUXILIARY PRODUCTS

- 1.A.3. Plastic

- 1.A.3.10 High barrier, laminated or co-extruded films

- 1.A.3.16 Compostable films

- 1.A.3.34 Polyolefin neutral films: PE, PP, OPP, transparent, white, pearly, etc.

- 1.B. PACKAGING

- 1.B.1. Primary packaging

- 1.B.1.1 Bag-in-boxes

- 1.B.1.19 Stand-up pouches

- 1.B.1.64 Printed/laminated flexible packaging

- 1.B.3. Transport packaging

- 1.B.3.1 Big Bags for transporting bulk material

- 1.B.3.49 Industrial bags

- 1.C. COMPLEMENTS, CONSUMABLES AND AUXILIARY PRODUCTS

- 1.C.1. Closures and dispensers

- 1.C.1.1 Resealable openings for flexible packaging

Prodotti

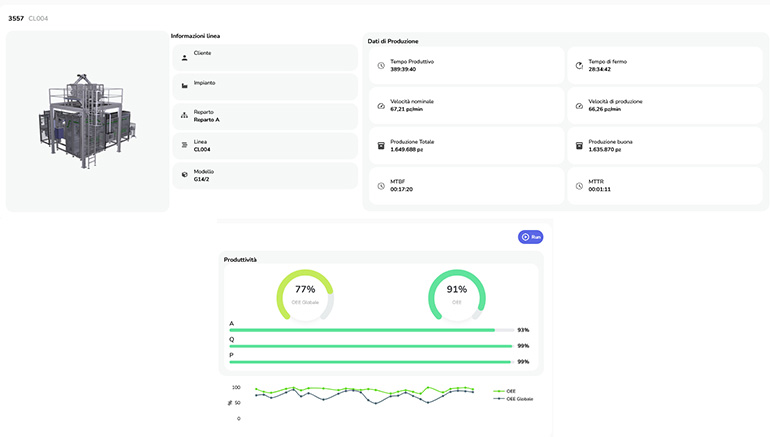

The new MIND platform

The MIND platform - set up in 2024 with the integration of the MIND Industrial Internet Of Things cloud platform functions for the real-time monitoring of packaging lines and the MIND Care document application - will be integrated in the coming months with important new developments which will further increase its functionality and capacity to support customers.

Major innovations include the integration of maintenance management, which will make it possible to monitor in detail any wear and consumption of the mechanical components, offering an immersive, real-time view of operations. In addition, it will be possible to configure customised alerts regarding the main KPIs, such as performance, yield and quality, but also the telemetry systems, alarms and the recurrence of certain problems, enabling pro-active diagnoses to increase productivity.

What’s more, with the introduction of predictive models based on artificial intelligence, the platform will allow for increasingly precise and prompt decision-making processes, anticipating any problems and optimising operating efficiency. Finally, the new integrated customer portal will simplify the management of assistance and tickets, guaranteeing the user a centralized and intuitive experience.

Fres-co System®+

The fres-co System®+ module, which optimises the synergy between laminates and packaging lines, is a further step forward in Goglio’s offer. This innovative system makes it possible to track every reel thanks to a unique code inscribed on the core of the material, making all the information relating to the laminate, such as technical characteristics and production parameters, available in real time on the MIND platform. The integration makes it possible to automatically adjust the settings of the machine on the basis of the type of laminate used, improving the performance of the line and collecting precious data for the development of materials.

Thanks to fres-co System®+, Goglio can, therefore, offer customers the possibility of improving production efficiency, reducing waste and obtaining maximum performance from packaging lines.