Beckhoff, based in Verl, Germany, is a company of international standing, leader in the automation sector, with subsidiaries and distributors in more than 75 countries worldwide.

Since its founding in 1980, the continued development of innovative products and solutions with PC-based control technology has laid the foundation for the continued success of the company. Numerous automation technology standards, that have today become customary, were initially discovered by Beckhoff and subsequently placed on the market as successful innovations. The Beckhoff PC Control philosophy and the invention of the Lightbus system, the Bus Terminals and TwinCAT automation software, are milestones in automation technology and stand out as viable alternatives to traditional control. A real-time Ethernet solution, EtherCAT represents a powerful and innovative technology available to a new generation of control and regulation systems.

Beckhoff Automation Srl, the Italian subsidiary based in Limbiate (MB), was founded in 2002 and currently has two branches located in Bologna and Padua. All centres provide technical and commercial support.

Merceologia

- 5.A. INDUSTRIAL AUTOMATION AND ELECTRONIC COMPONENTS

- 5.A.1. Power electronics

- 5.A.1.10 Servo drives (DC and brushless AC.)

- 5.A.1.13 Drive systems

- 5.A.1.7 Electric motors

- 5.A.2. Automation and control systems

- 5.A.2.10 Hardware (pc - industrial personal computer)

- 5.A.2.19 Robotics

- 5.A.2.22 Supervision and monitoring systems, vision systems

- 5.A.2.28 Industrial software

- 5.A.2.4 Programmable logic controllers (plc)

Prodotti

Fast, flexible, and resource-efficient: PC-based control optimizes packaging machines

With PC-based control and EtherCAT, Beckhoff offers a control solution for highly efficient, flexible and resource-conserving packaging machines. Predestined for applications where high speed and precision are of utmost importance, the PC platform with its high-performance field devices is perfect for synchronizing all process and motion control workflows. The bottom line: work steps are accelerated, and the consumption of packaging materials declines. For example, the fast and precise recognition of print marks means that you can seal blister packs closer to the product they contain.

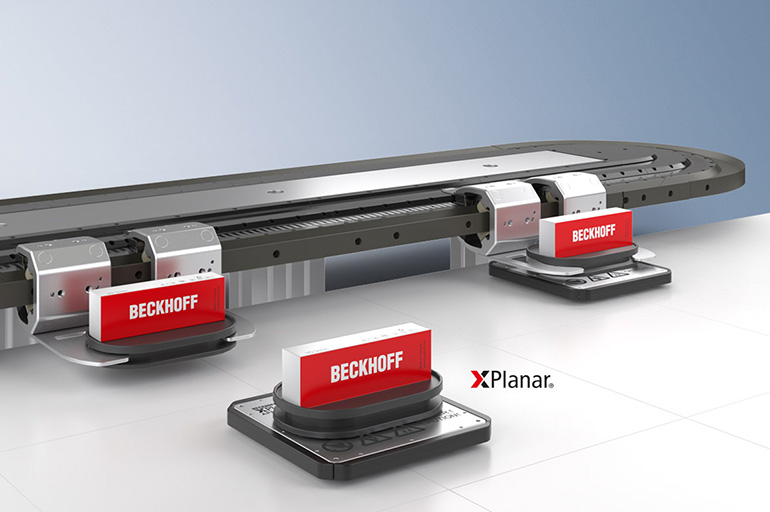

The Beckhoff automation portfolio comprises everything you need for a technologically and financially superior packaging solution. All control and drive components are scalable to meet the performance requirements of the respective application perfectly. Optimally coordinated hardware and software interfaces as well as extensive expertise in implementing each process step guarantee a high level of process stability. Innovative products such as the XPlanar and XTS smart product transport systems ensure lasting competitive advantage and revolutionary solutions such as MX-System enable completely control cabinet-free automation solutions in machine and system engineering.

Intelligent product transport with XTS and XPlanar optimizes packaging machines

With PC-based control and EtherCAT, we offer highly efficient and resource-saving automation solutions for packaging machines. In particular, our intelligent transport systems are ideal for applications where high speed and precision are essential and are perfect for automating all packaging processes.

The XTS combines the advantages of a linear transport system with those of a rotary solution. Products can be transported independently of each other. Since both straight sections and the curves are used to transport materials, there are no empty trips, making for a faster overall packaging process. The packaging steps are optimally synchronized, which minimizes downtimes. Machine footprints can be reduced by up to 50% with the XTS. With the intelligent XPlanar transport system, free-floating planar movers glide smoothly over freely arrangeable planar tiles along six axes, without colliding with each other.

With XPlanar, packaging machines can be designed in entirely new ways. Since the XPlanar tiles can be arranged to suit any machine design, product streams can be freely directed. Quick setup changeovers shorten the machine downtime and allow for the economic production of small lot sizes. A further advantage is that the MX-System allows automation solutions to be implemented completely without control cabinets, resulting in huge savings in terms of space and wiring time and costs. The combination of baseplate and function modules in this modular system combines all the tasks and properties of a control cabinet: power supply, fuse protection and power distribution, generation and monitoring of auxiliary voltages, sequence control with inputs and outputs, control of motors and actuators, and the connection level for the field devices. The consistently systemic approach greatly reduces the effort required for planning, machine installation, and maintenance. The system footprint is reduced, and system availability and flexibility are also increased