The Robatech Group, headquartered in Switzerland, is a leading global manufacturer of innovative and sustainable adhesive application solutions for industrial hot-melt and cold-glue applications.

Robatech Italia S.r.l. u.s., founded in 1982, is a direct subsidiary based in Cesena. Its modern premises house a fully equipped test laboratory, a training center, a large stock for spare parts and entire gluing systems, and a repair and retrofit workshop. 30 employees, some with more than 20 years of work experience at Robatech, get gluing projects up and running and ensure smooth operation of adhesive systems. Robatech provides fast and reliable after sales service and a 24/7 hotline.

“Green Gluing” is the concept that makes Robatech so different. Innovative and energy-efficient gluing systems reduce adhesive consumption and operating costs. Robatech products support customers in achieving more sustainability due to a modular design, very long service life, and excellent gluing results.

Everyone at Robatech loves to walk the extra mile for optimizing gluing processes.

Prodotti

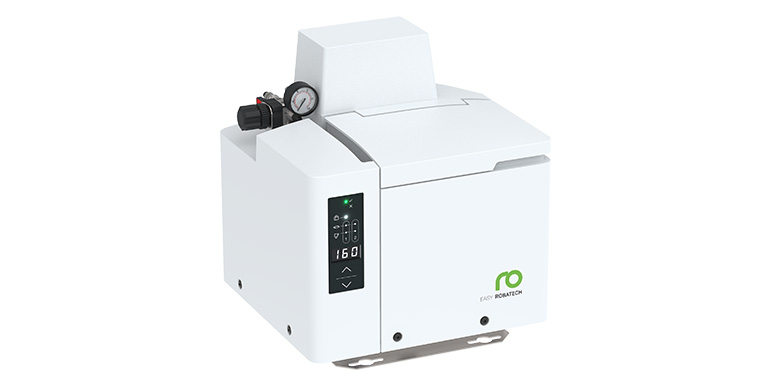

EASY - THE SMALL ADHESIVE MELTER FOR SIMPLE APPLICATIONS

The small, compact Easy melter is ideal for gluing simple applications such as folding boxes, trays, paper bags, paper cups or paper cones. It offers a maximum melting capacity of 2.5 l/h and allows two heated hoses to be connected. Customers get the functions they really need:

- manual pump pressure control;

- temperature lowering

- 3-zones heating management for the melter, heated hose and application head.

The benefit: an energy-efficient, basic melter of Swiss quality with attractive price/performance ratio.

Precise and fast gluing of primary packaging

Primary packaging of food and medicines puts high demands on the gluing process. Robatech offers reliable system components that allow to glue small packages precisely and safely even at high speeds. Robatech is synonymous with consistently high-precision adhesive application with a clean cut-off, safely and cleanly bonded products, high process reliability, high production speeds, and low energy consumption.

Economical and reliable gluing of secondary packaging

Robatech enables an efficient and, at the same time, sustainable gluing process in secondary packaging. Whether the packaged products are placed in secondary packaging through standard top-loading or horizontal cartoning, or whether on-demand packaging systems are used, the adhesive process is essentially the same. Robatech’s adhesive application systems apply hot melt adhesives economically and still glue secondary packaging reliably. Maximum system availability increases production by reducing downtime, while industry-leading energy efficiency saves resources and reduces operating costs.