Established in 1966, Ronchi Mario SpA is specialised in the construction of packing lines for liquid products.

Ronchi employs mass or magnetic flowmeter technology for filling, which guarantees extremely high dosing accuracy and ensures considerable simplicity in line management. Today Ronchi has earned its position as one of the main reference suppliers for various multinational groups in the detergent, personal care, pharmaceutical and food industries.

The Ronchi product range includes also:

- bottle unscramblers for high production speeds, and suitable for handling different bottle formats, with minimum change-over time from one format to another;

- bottle orientors, matching all orienting requirements (containers with handles, with off-centred necks, etc);

- automatic machines for placing unstable bottles into pucks and removing them from the pucks at the end of the cycle.

In its modern and highly equipped 20.000 sq.mts. factory, Ronchi Mario SpA manufactures over 90 machines a year, more than 85% of which are exported. In January 2017 Ronchi inaugurated a new “Zero Emission” plant near the historic site, equipped with photovoltaic system, rainwater recovery, heat pump heating system; a “green building” model for sustainable industrial development. Ronchi Group, in addition to an extensive worldwide network of agents and distributors, operates directly over the American, UK and Far East markets through Ronchi outlets: Ronchi America in Atlanta (GA), Ronchi UK in Coventry and Ronchi Asia with offices in Bangkok (Thailand), Uttar Pradesh (India) and Shanghai (China).

Settori di destinazione

Merceologia

- 2.A. MACHINES FOR PRIMARY PACKAGING

- 2.A.1. Filling and dosing machines

- 2.A.1.3 Filling machines - Liquid / viscous products

- 2.A.2. Closers and closing systems

- 2.A.2.1 Capping machines (application of pressure/deformation cap)

- 2.A.3. Fillers - Closers - Monoblocks (FS Machines) of

- 2.A.3.1 Rigid and semi-rigid containers (cans, bottles, vials, bottles, cans, tubes),

Filling-Capping Monoblock EXACTA/R 12/6

EXACTA/R 12/6 is the most renowned filling-capping monoblock in a new and technologically advanced version. Specially designed for cosmetic, chemical,food & pharmaceutical industries, it is equipped with 12 filling stations with magnetic inductive flow-meters (as for all filling machines of the Exacta series, it is possible to fit mass-type flow-meters); it is manufactured in “ultra-clean” version and all parts in direct contact with the product, from collector to filling nozzles, are made in 316L steel. New closed loop C.I.P. system ensures the most efficient washing process, automatically carried out through a simple touch from the operator’s panel. It is provided with 6 capping stations suitable to handle all kind of caps and pumps: each of the capping stations is equipped with an independent servo-motor which ensures maximum production flexibility and extremely precise torque control.

EXACTA/R 12/6 is the most renowned filling-capping monoblock in a new and technologically advanced version. Specially designed for cosmetic, chemical,food & pharmaceutical industries, it is equipped with 12 filling stations with magnetic inductive flow-meters (as for all filling machines of the Exacta series, it is possible to fit mass-type flow-meters); it is manufactured in “ultra-clean” version and all parts in direct contact with the product, from collector to filling nozzles, are made in 316L steel. New closed loop C.I.P. system ensures the most efficient washing process, automatically carried out through a simple touch from the operator’s panel. It is provided with 6 capping stations suitable to handle all kind of caps and pumps: each of the capping stations is equipped with an independent servo-motor which ensures maximum production flexibility and extremely precise torque control.

Its electronic cam ensures rapid and automatic format change over, other than offering the greatest flexibility for handling different type of pumps with dip-tubes having different lengths. Also, the dip tube is positively guided and controlled throughout the insertion process. This new machine can handle screw-on caps, press-on caps and caps to be oriented.

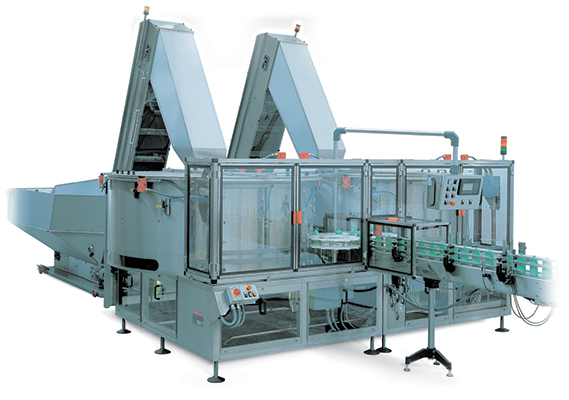

Rotomatic bottle unscramblers

Rotomatic is a line of bottles unscramblers suitable to handle plastic containers of any shape and size. This line of machines is designed to allow for a large variety of formats to be handled with the same set of change parts (selectors), providing maximum reliability. These machines are also available in monoblock, combined with bottle orienting sections. For high output requirements, the unscramblers are available in the Bi-Rotomatic version, i.e. equipped with double bottle selections hopper.

Rotomatic is a line of bottles unscramblers suitable to handle plastic containers of any shape and size. This line of machines is designed to allow for a large variety of formats to be handled with the same set of change parts (selectors), providing maximum reliability. These machines are also available in monoblock, combined with bottle orienting sections. For high output requirements, the unscramblers are available in the Bi-Rotomatic version, i.e. equipped with double bottle selections hopper.