Founded in 1973, Prati is a leading brand in the label finishing industry at international level. Acknowledged as one of the top innovative companies in the sector, it has paved the way for revolutionary technologies able to offer customers a competitive edge in the finishing of labels and packaging in various markets: from the demanding pharmaceutical, food, wine and spirits sectors to cosmetics, in which elegance and creativity are a must.

Designing every project in accordance with the specific requirements of a rapidly evolving market, the company offers customised solutions for post-print finishing, inspection, die-cutting, matrix stripping, rewinding, cutting and overprinting. With over 4,000 machines installed, Prati operates at international level, with offices in Italy and branches in the American continent.

The company holds certifications for its integrated quality, environmental and workplace safety management systems, in compliance with the following international standards: ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018.

Prati USA LLC: 4101 McEwen – Suite 368 Dallas, TX 75244 – USA,

+1 913 908 8607

[email protected]

Settori di destinazione

Merceologia

- 2.D. LABELING, CODING AND MARKING SYSTEMS

- 2.D.1. Labelers, printers, markers

- 2.D.1.1 Labeling machines

- 2.D.1.2 Print & Apply

- 2.D.1.7 Label dispensers

- 2.E. AUXILIARY EQUIPMENT

- 2.E.2. Inspection and control devices

- 2.E.2.3 Label/bar code control devices

- 2.E.3. Auxiliary equipment

- 2.E.3.10 Machines for finishing of labels and packaging

Prodotti

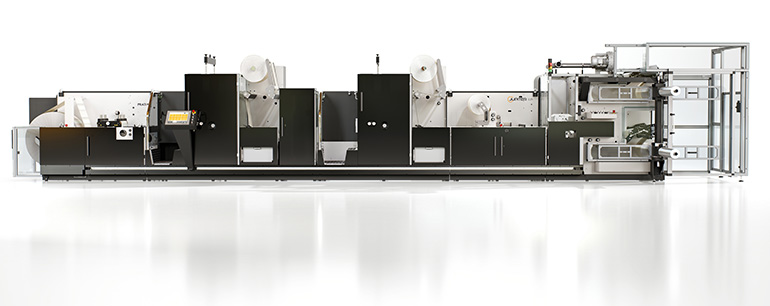

JUPITER. Control and converting line Wide Modular that offers maximum safety, quality without defects and modularity for the flawless inspection of labels and flexible packaging. The complete modularity makes it possible to offer a totally configurable machine.

Characterised by high speed (up to 400 m/min) and a high band width (670 mm), it stops only to permit the elimination or correction of predefined defects. It can manage materials from 20 to 350 µm with three different rewinding tensions for unsupported film, self-adhesive labels and “clear-on-clear” labels.

DIGIFASTone. Completely digital line both in the print reel finishing and in the die-cutting, much appreciated for its versatility. It works on a wide range of materials from 12 to 350 microns, including self-adhesive, clear-on-clear and wrap-around labels, shrink sleeves, plastic film, and unsupported paper and plastic materials. Thanks to the completely digital set-up, equipment such as flexible dies, magnetic cylinders, print cylinders, cliché rolls and anilox rollers is no longer required, thus allowing operating costs to be reduced.

DIGIFAST20000. Designed to be integrated with the HP Indigo 200K printing machines, and not only, it can carry out various types of finishing: from varnishing to total or selective printing, from decoration to the finishing of jobs on both roll and sheet for further processes. Digital embellishment, assigned to the new JetFx unit, applies spot varnishing in register on the reel, in combination with the lamination unit, increasing productivity and reducing costs and set-up times. Ideal for a wide range of applications in flexible packaging.

SATURN Omnia. An extremely flexible “all in one” finishing solution, it can carry out a number of processes on a single line: from roll to roll, roll to sheet and roll to stack. It allows for the creation of wet glue labels without the need to invest in new equipment. Highly appreciated among the innovations is the possibility of operating with semi-rotary die-cutting.

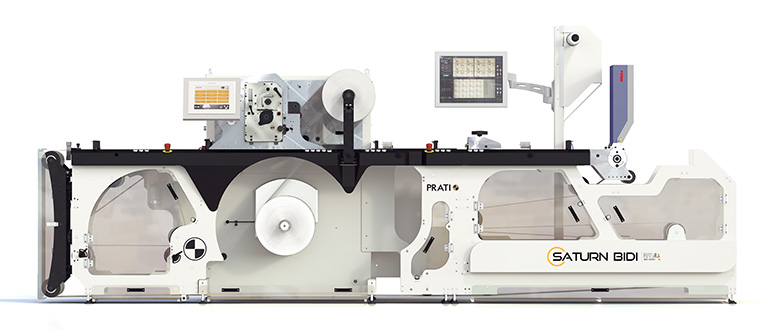

SATURN Bidi. Safety is the watchword of this control and inspection table for digitally printed labels for the cosmetic and pharmaceutical sectors. Thanks to the two-directional configuration, it ensures 100% control of quality, certifying “0” defects in printing, counting and cutting precision.

DIGICOMPACT. Ergonomic par excellence, it can perform analogue and digital finishing of all materials (from roll to roll, roll to sheet and roll to stack) in only three metres of space, and is increasingly in demand due to the increase in digitally printed labels. The flexo unit is suitable for spot printing and varnishing. Equipped with a low energy-consumption cold UV curing system, there is no need for chillers.

VEGA+. It is a hi-tech, modular, customisable, converting, finishing and control line, equipped with an inspection unit installed after the die-cutting unit. Completely self-assisted and designed for long runs, Vega+ is ideal for producing high quantities of labels. It can be combined with the BKL module for the offline production of booklet labels, and with the STAR+ glueless rewinder, reaching a speed of 250 m/min.